The journey of new chemistry

The journey of new chemistry: bringing improved productivity, lower costs and improved sustainability to our turf management systems.

Research & Development (R&D) companies like Syngenta continue to rise to the challenge of creating solutions to meet the needs of our customers and modern societal demands. Development is increasingly focused on improving product safety, negating environmental impacts, and adhering to high stewardship standards through close collaboration, to ensure solutions can be delivered for challenges now and in the future.

Recently, we have seen a range of more efficient solutions that reduce the number of product required to be applied, either in frequency or volume, while still managing the issue at hand. These scientific developments provide a good economical outcome for turf managers and agricultural producers as these tools increase productivity and reduce costs, in a sustainable manner.

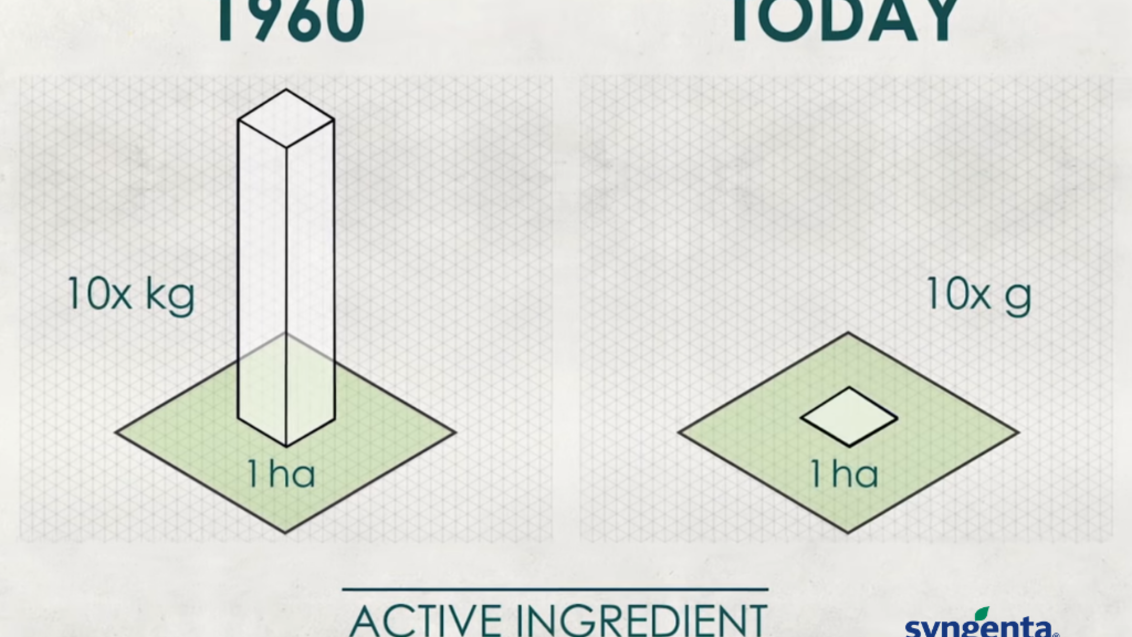

Since the 1960’s we have seen a drastic reduction in the amount of active ingredient applied. When once we would have applied tens of kilograms per hectare, we now apply tens of grams per hectare for the same or better efficacy outcomes. This change is driven by new R&D chemistry that has greater precision. But along with that precision and efficacy there is a range of additional benefits that new chemistry brings, such as longevity and product safety improvements.

We often state today that we don’t find active ingredients “by chance” like we once may have. We design them with consideration; to be safe to operators and consumers, to be safe to the environment, as well as effective and easy to use, while also being cost effective. The ability to be able to design solutions means that we can tailor them to the end target; improving efficacy, toxicology and environmental profiles of products.

Over the last 30 years we have lost 30% of active ingredients globally because they no longer work as effectively, or no longer meet society’s expectations. A recent example in our industry is the removal of chlorpyrifos from use on residential turf areas and areas accessible to the public. This was largely driven by its toxicological profile. But importantly there is a range of less impactful, more targeted insecticides on the market, that have a better environmental and operator fit, that can fill the space of this removal. One such product that you will be familiar with is Acelepryn Insecticide which is exempt from poison scheduling and provides long residual control.

To continue to meet the changing needs today, we need to design for the future, ensuring we have solutions to replace older chemistry as they are retired for a range of reasons. Today Syngenta invests around $1.3 billion per year into researching new solutions. This is our commitment to ensure solutions exist into the future. A single product takes around $300 million dollars of investment to bring to market including continued development and product support to move it into other uses. This development covers optimisation to reduce waste, environmental and toxicology profiling, as well as efficacy. Our development programs today are been designed for the needs anticipated for 5, 10, 15 even 20 years into the future. With such a long process we take into consideration what expectations and needs will likely be relevant in the future and design our actives to meet those needs.

A great example of this continued investment is Syngenta’s newest SDHI Group 7 fungicide, Posterity, which was recently launched in the Australian turf market. It was a long process to develop this high-efficacy, low-use-rate fungicide that delivers a real step change in efficacy on Dollar Spot control. Posterity brings value to the industry; due to the longevity of control it delivers along with its environmental and toxicology profile that has earned it an unscheduled status. Products like these bring direct benefits to end users of both the product and the turf surface.

An important step in “greener chemistry” development (as it is often coined) is preventing and avoiding waste, waste elimination, and to aim to reduce environmental impact while meeting sustainability goals and requirements. This starts with the R&D process, but also continues to flow through our entire supply chain. For example, Casper herbicide, which is a relatively new formulation of an old active ingredient – Dicamba – is applied at 1kg/ha with the product supplied in 1kg packs. The standard rate for this herbicide – without Syngenta’s smart formulation technology – is 4L/ha, with the product supplied in 20L drums. Casper’s unique formulation allows for a vast reduction in packaging. The product’s reduced product requirements and lower rate of active ingredient per hectare has a positive impact on the environment by reducing carbon in the transport system due to smaller and lighter packaging, and importantly a reduction in waste material to be disposed of at the end of the product’s use.

In the here and now, Syngenta products continue to deliver due to formulation optimisation. R&D not only focuses on active ingredients, but also on getting them into a formulation that will enhance performance. This is driven by the choices and combinations of inert formulation elements and specifically designed surfactants. These enhancements do many jobs including protecting the active ingredient from degradation, stabilizing the formulation in storage, maintaining formulation suspension, ensuring ease of use and improving formulation stability in the spray tank. Development of final formulation mix and formulation type are chosen to deliver the most effective efficacy outcome with the lowest volume of active ingredient. An example of this formulation optimisation is a product like Pennmag pre-emergent herbicide. The selection of the active ingredient raw material in the Pennmag formulation was chosen to have more of the active component within the active ingredient compared to generic formulations. The benefit to customers using Pennmag is a higher level of control that will last for longer above the critical concentration in soil needed to prevent weed germination. Another example is the carefully chosen surfactants in Primo growth regulator. These are selected to ensure the speed of uptake is at a rate that gives maximum efficiency, while providing excellent plant safety. This is a clear difference to some generic formulations that regularly observe levels of phytotoxicity after application.

With new technology also comes the need for continued support, and stewardship of products and applications. Ongoing engagement helps us relay knowledge of our products to customers, while allowing for valuable feedback on what the next generation of solutions may look like. As we move into the next 5-20 years, we will continue to see greener chemistry that is created for solutions with ever improving safety, environmental and toxicology profiles. Not all products are made equal and Syngenta will continue to develop new solutions that perform to the highest levels while meeting society and customer expectations.

Written by Michael De Luca, Technical Manager for Syngenta Professional Solutions.