Defining the terms

Firstly, let’s work through the definitions, because we need to all be on the same page before we can get into the fun details. You have probably heard these terms many times before – adjuvants, non-ionic surfactants, spreaders, stickers, penetrants, emulsifiers, wetting agents etc. But what exactly are they? And, for instance, which are suited for use on turfgrass when including with a pesticide spray mix?

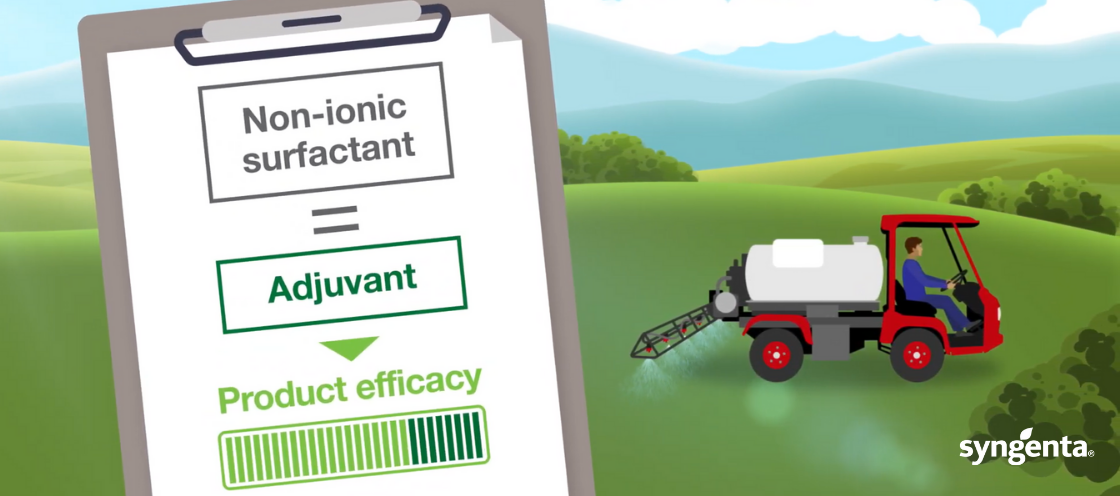

Adjuvants is the general term for materials added to spray solutions to improve the performance of plant protection compounds, like herbicides, insecticides, miticides and some fungicides. They form a broad range of products including surfactants, spreaders, penetrants, stickers, crop oils, anti-foaming agents and compatibility agents.

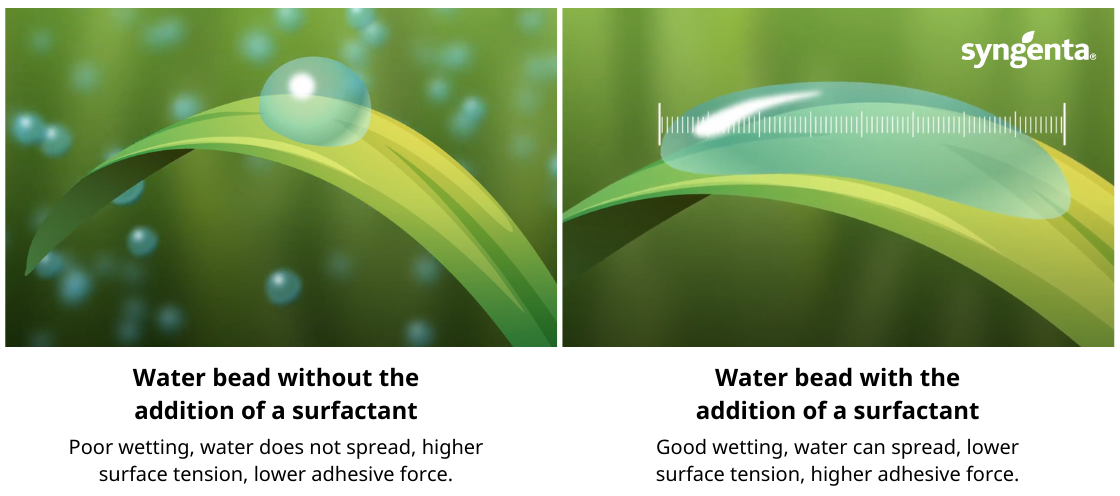

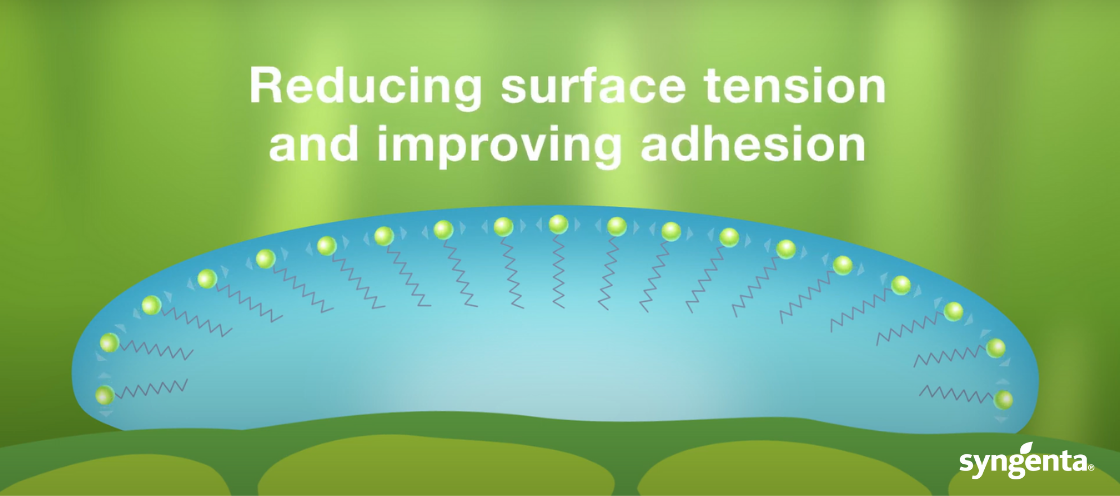

Surfactants are a type of adjuvant, and the most commonly used by turfgrass managers. The word surfactant comes from the contraction of "SURFace-ACTive-AgeNT", but they are also known as spreaders, penetrants, stickers, emulsifiers, or wetting agents. A surfactant is a chemical substance that increases the spreading, retention and/or penetrating properties of a liquid by lowering its surface tension. There are four main types of surfactants: Anionic surfactants, Cationic surfactants, Non-ionic surfactants and Amphoteric surfactants.

Non-Ionic Surfactants (NIS) are water soluble chemical and lipid compounds, comprised of linear or nonyl-phenol alcohols and/or fatty acids, that are not molecularly charged (positive or negative) and are non-reactive. Non-ionic surfactants are most commonly used as soil wetting agents because of their universal fit, and a high degree of turf safety.

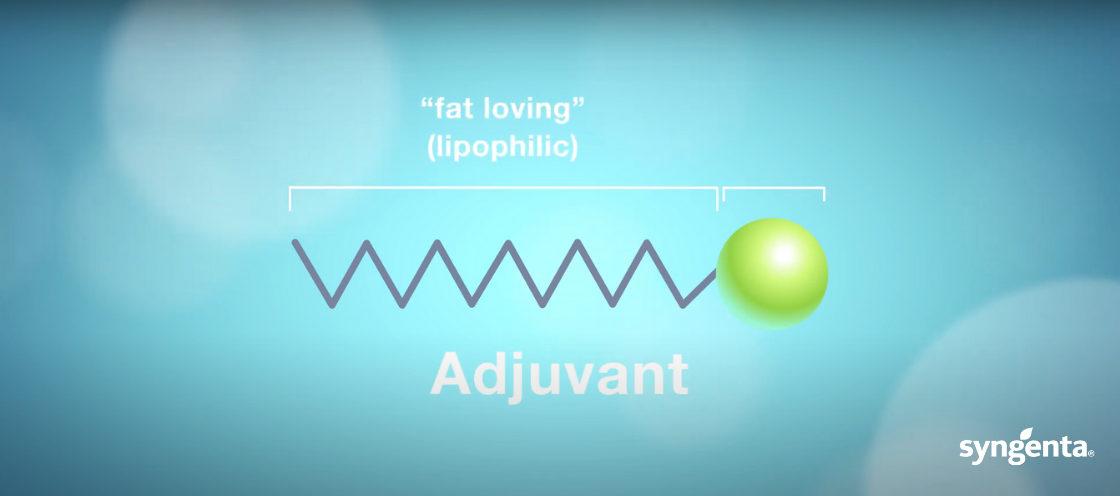

Anionic Surfactants are those in which the active portion of the molecule attached to the lipophilic (‘fat loving’) segment has a negative ion (anion) charge. These are also used in blends of soil wetting agents with high penetrating abilities due to the negative charge.

Cationic Surfactants are those in which the active portion of the molecule attached to the lipophilic (‘fat loving’) segment has a positive ion (cation) charge. These were the first type of soil wetting agents but carried a risk of phytotoxicity.

Amphoteric Surfactants are neutrally charged as they carry both a positive and negative charge. They can form positive or negative charges when in solution, depending on the pH of the water.

In professional turf management, the most common types of adjuvants used are spreader and penetrants:

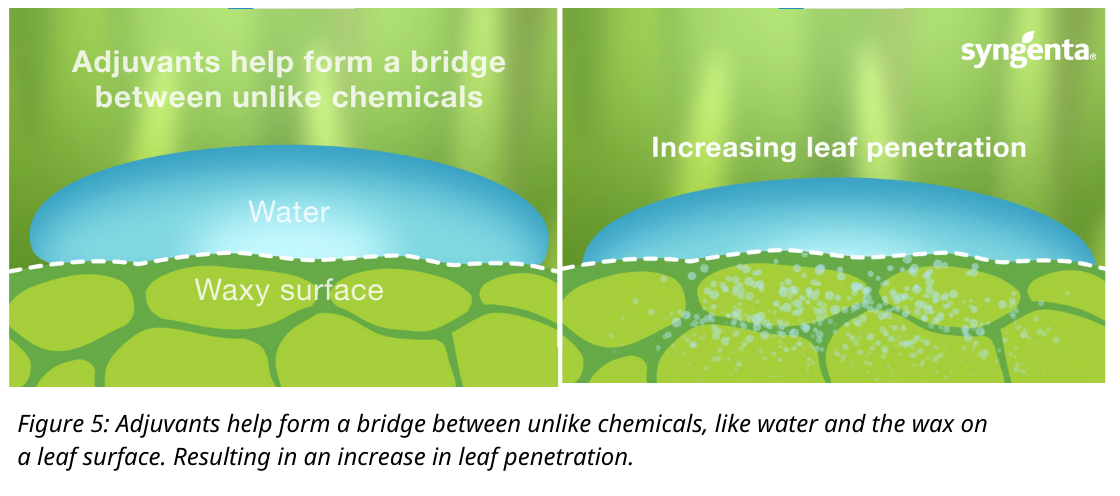

Spreader type adjuvants are used where good coverage for short periods is the primary objective. Most often used in conjunction with foliar applied products to increase the spread over the treated surface and increase sticking and herbicide uptake. For example, the addition of an adjuvant is recommended on the MONUMENT® and CASPER® Herbicide labels to ensure full coverage across difficult to control weeds such as sedge due to their waxy leaf coating. Another example is BARRICADE® Herbicide, which when mixed with MONUMENT® Liquid Herbicide is supported by a surfactant to move evenly across emerged plants of Winter Grass.

Penetrant type adjuvants are used with products to improve the transfer of active ingredients from the leaf surface to its interior tissues. They increase uptake and result in greater herbicide activity on difficult-to-penetrate weeds. Some soil wetting agents are also classed as penetrants allowing for greater evenness of penetration. For example, when treating Fairy Ring with VELISTA® Fungicide, a penetrant helps to move the active into the zone of activity evenly.

Always refer to the product label in order to choose the correct additive for a specific product.